Behind the Development of the TST WORX R3 Velocity Stacks

When it comes to motorcycle racing, you often go to great lengths to gain a little extra edge, and the TST WORX Velocity Stacks are a prime example of such an effort. Throughout our R3 Superbike Build Series, you’ve watched us modify almost every component of our R3, and turned it into a proven track weapon. But one of the few things we hadn’t modified, were the stock velocity stacks, and in looking at a stock component, we couldn’t help but think there had to be some room for improvement… and let me tell you…there was. After all, we have the ASRA Moto 3 Championship trophy to prove it.

We wanted to improve the performance of our Superbike R3, which was already a finely tuned, heavily modified machine. Every component on the machine comes together to create an R3 specifically designed for racing, and with an increased RPM range and shift in power to the top-end, the velocity stacks for the Superbike R3 needed to be perfectly designed to accentuate specific performance characteristics.

The goal was simple, but the execution was far from it. The TST engineering team spent weeks researching intake dynamics and volumetric efficiency, then more time designing and testing different variations of velocity stacks. With extensive research, hundreds of dyno runs, and on-track testing, the R3 Superbike Velocity Stacks were taking shape. All of the hard work culminated in the final design, providing a 9% increase in peak horsepower and a small bump in peak torque values. That’s a massive improvement for an already insanely fast R3.

After setting multiple lap records and establishing an almost permanent residence on the podium, our Moto3 National Championship winning bike had solidified itself as a true success of engineering and TST design.

|

|

This is when the question hit us – how much horsepower can we add to an unmodified R3 with our WORX Velocity Stacks? After all, the Superbike R3 is heavily modded and built for racing, but could we pull similar numbers with a stock bike? We had to know. The previous iteration of velocity stacks wouldn’t provide the same results on a standard bike, so our engineers went back to the drawing board….well in this case, computers, to work on a design specifically tailored towards a stock or mildly modified R3. The redesign effort began by developing an equation that would allow the creation of multiple velocity stack designs, each specifically targeting multiple RPMs. This equation would enable us to create a valuable baseline, not just for the Yamaha R3, but any other motorcycle as well.That equation consists of the following factors:

Constants:

– Reflective harmonic (how many cycles the pressurized air will make in the intake track)

– Speed of Sound

Variables:

– Effective Cam Duration

– Intake Tract Length

– Target RPM for performance increase

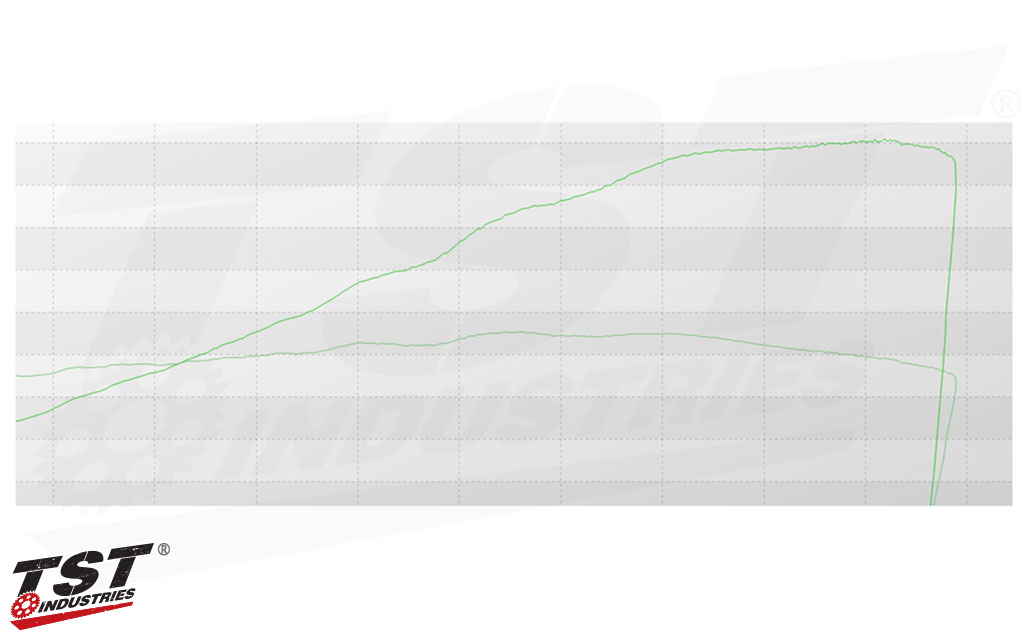

After manufacturing several prototypes, the team spent hours on the dyno running various configurations of the designs in an effort to obtain the best overall performance increase. We noticed that a trend was appearing when we paired two velocity stacks of the same length on the R3; while the target RPM would see an improvement in torque and Hp, the segment before the gain would see a decrease. This trend resulted in a wavy horsepower graph like the one shown below.

|

Waves are cool in the ocean, but when you see them on a dyno chart, there’s room for improvement. Although we did see an increase in power, it wasn’t meeting our goal of creating smooth power delivery across the board, and was negatively affecting riding as you could feel the unevenness in the delivery.

This was a mild set back, but after doing more research, our engineers discovered data detailing the effects of the velocity stacks around the targeted RPM. They found that the intake pulse only helps volumetric efficiency through a narrow range of RPM. Above or below a certain range, the intake pulse actually decreases the efficiency of the engine. We were able to confirm our hypothesis through more dyno testing and prove that the areas experiencing the decrease in efficiency were being compounded due to each velocity stack and resulted in noticeable power loss.

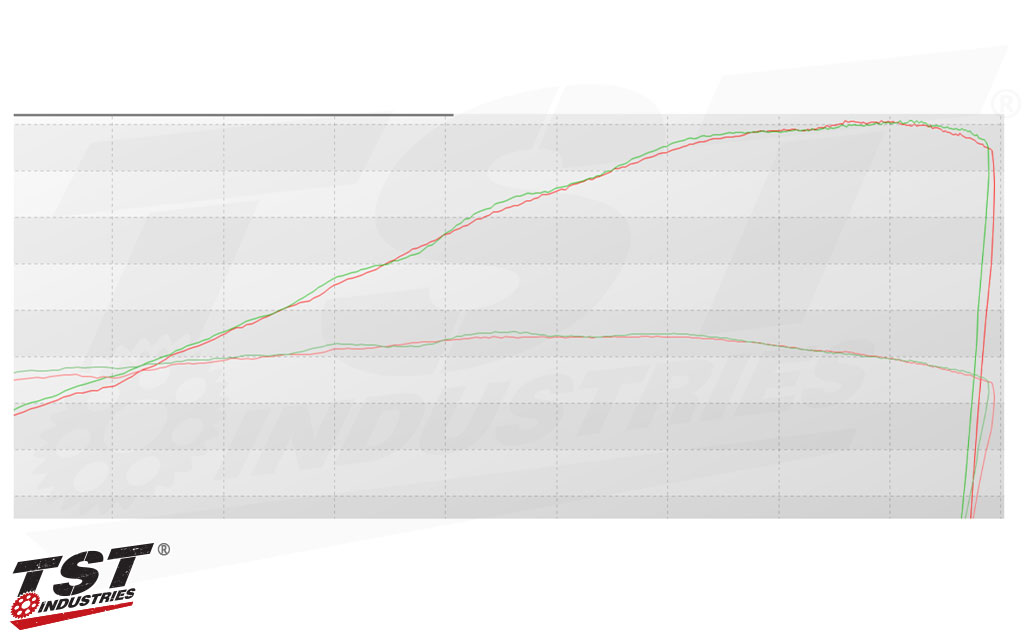

After returning to the baseline equation and correcting for the issue, the development of two different length velocity stacks was brought to the table. This solution would smooth the power delivery across the RPM range, raise the peak power RPM, and broaden the torque and power curves. It allowed the team to tune the optimized RPM of one stack to counteract the negative effect of the other. While peak performance may not be as substantial with this method, it strikes a great balance of improved performance and smooth delivery, which our test riders have shown preference for over a choppy/peaky delivery.

|

This dyno chart shows the difference in HP with two same-length velocity stacks compared to a set that is tuned to work together.

The tests at our R&D facility were showing positive results, but we needed to see real world results. After finding a tester outside our pool of racers, we installed a set of WORX Velocity Stacks, as well as the rest of the TST WORX Pack components on a stock R3, and sent it off into the world. Over the next several months valuable feedback was provided by the test rider, and helped shape the decisions in subsequent re-tuning of the flash program to better suit the overall goals we had for the package. We were extremely happy with the results, as was the rider.

If you’ve read our previous blog post about manufacturing tail lights, you know that it takes a lot of time to manufacture a part and can present new problems along the way, but this isn’t our first time making unique parts….hell, that’s what we are known for. We were determined to manufacture these in a way that enabled the rider to simply bolt them on and had a completely reversible install method, meaning that there’s no modification required and you aren’t stuck having to replace stock parts if you decided to take them off. This is very different than our original Superbike R3 velocity stack design which had permanent modifications to the airbox.

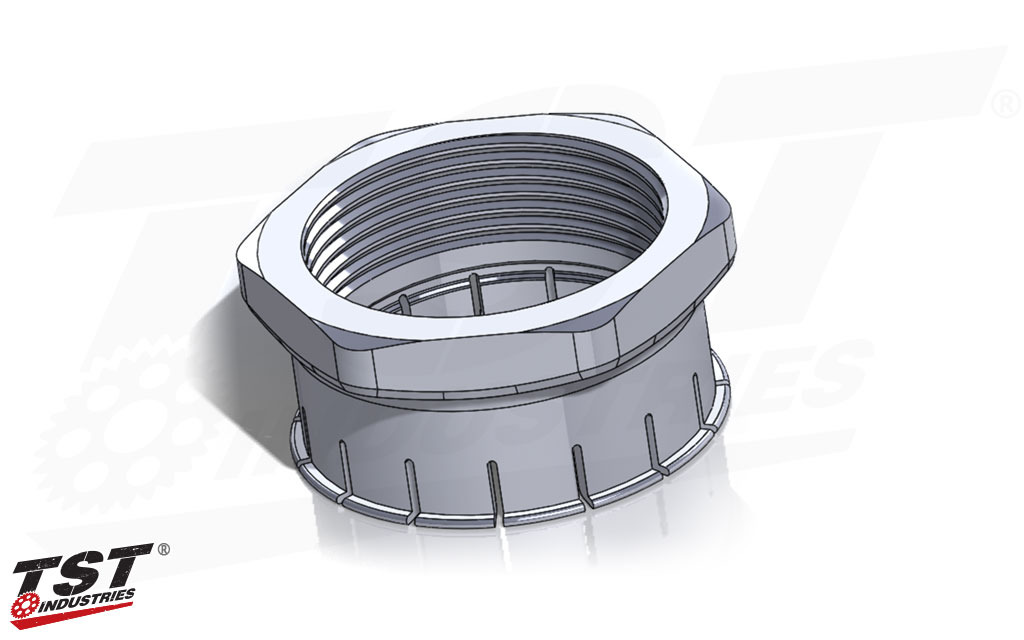

This meant that our engineering team, once again, had to synthesize a unique solution to a unique problem. After several design types were prototyped and tested, a two-piece system was chosen that would thread together and allow the main airbox component to remain unchanged. Our engineers designed a thread standard that was easy to manufacture and very secure. The engine facing half of the velocity stack was designed based on reverse engineered throttle body shape to allow precise fitment, with a snap fit onto the lip found on the throttle body.

|

|

The shape of the velocity stack components was in fact complicated by adding all these functional features but we were able to find a suitable manufacturing technique using chemically inert materials. We manufactured our first test batch of production version Velocity Stacks to be thoroughly tested and put through the paces…and they didn’t disappoint. After months of testing, we saw that these prototypes were providing the same results as our in-house prototypes. This is exactly what we wanted to see and meant we were ready for full production.

We introduced our velocity stacks at the beginning of 2020 to a great response. It’s clear that the results speak for themselves, and through our engineers drive for excellence, we are able to offer a true bolt-on component that provides measurable horsepower gains and smooth power delivery. The unique design, extensive research, and proven results of this project have firmly planted the TST Industries flag in the race component world, even catching the eye of the FIM Technical Director, which is the governing body of racing organizations such as MotoGP and World Superbike / Supersport. With interest in getting a set of TST WORX Velocity Stacks for independent testing, it’s a real possibility that our stacks could be seen in future World Supersport 300 racing classes.

TST Racing

TST Racing

Blog

Blog

YouTube

YouTube

Facebook

Facebook

Instagram

Instagram

I have a Power commander In my z400 can I still install the WORX VELOCITY?

How does the offset velocity stack design compare with stock RPM charts?

Stock being stock pipe, tune, and velocity stacks compared to the WORX package with the TST velocity stacks.

Is it possible to tune the motor (without breaking into internal modifications) using velocity stack engineering for low and mid-range gains while maintaining the same gear and sprocket ratios as stock?